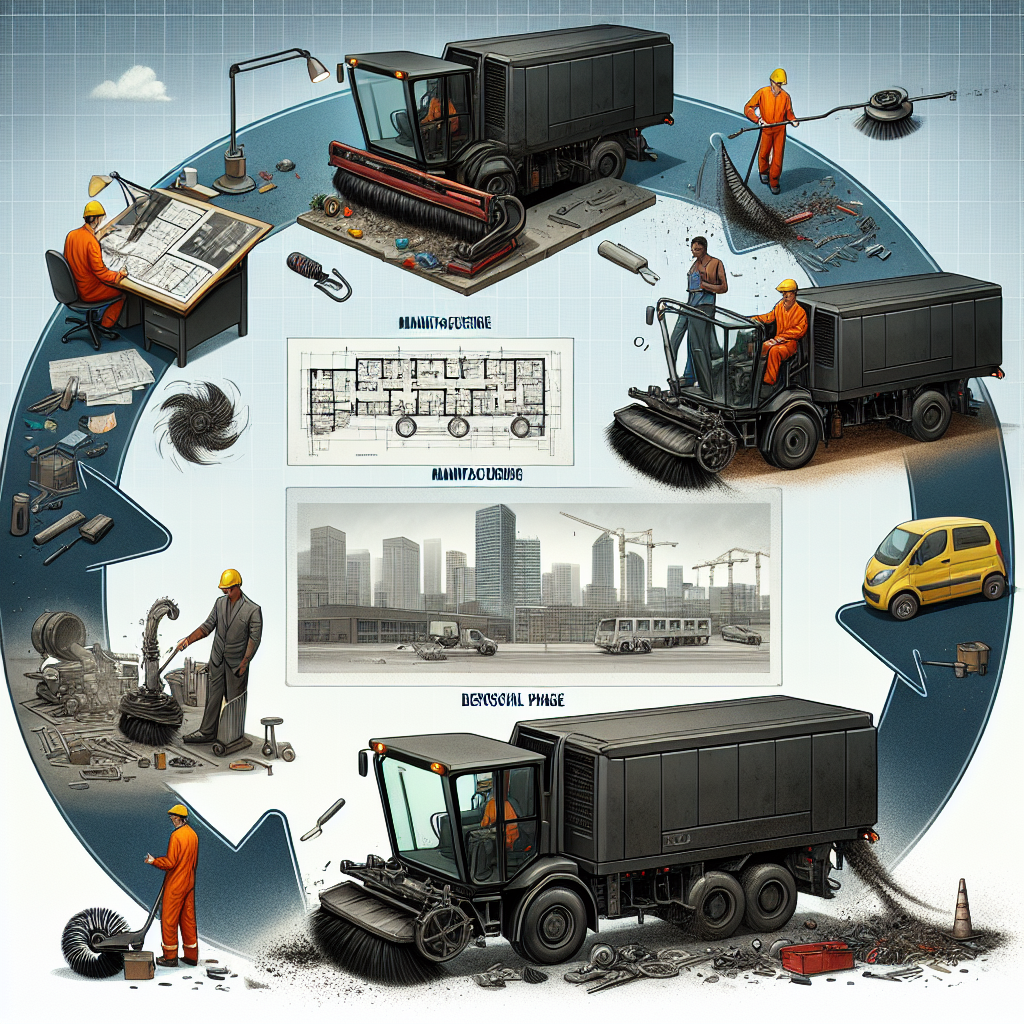

The Lifecycle of Power Sweeping Equipment: From Design to Disposal

Have you ever wondered how those big machines that clean our streets come to be? Well, today we're going to learn about the life of power sweeping equipment! These machines are essential for keeping our neighborhoods clean and safe. Let's follow their journey from the very beginning when they're designed, all the way to their final days when they're disposed of.

Step 1: Design

The lifecycle of power sweeping equipment begins with design. Engineers brainstorm and create plans for these machines. They think about the best ways to make them effective and efficient. They consider what types of debris the sweepers will need to handle, the size of the streets, and how the machines should be powered. These designers use computers to create models of the sweepers, testing different features such as brushes, suction power, and storage capacity. It's like building a giant puzzle where every piece needs to fit perfectly!

Step 2: Manufacturing

Once the design is ready, it’s time to build the power sweeper. This step is called manufacturing. The parts of the sweeper are created in factories. Skilled workers and machines work together to assemble the sweeper, much like putting together a complicated model kit. The sweeper is made from materials like steel, aluminum, and strong plastics to ensure it can withstand harsh conditions. After assembly, the machines are tested to make sure they work correctly. Only the best machines are sent out for sale.

Step 3: Distribution and Sales

After being built, the sweepers are ready to be sold to cities and companies that need them. They are transported from factories to dealerships or directly to the buyers. In this step, salespeople showcase the benefits of the sweepers to potential buyers. They highlight their sweeping capabilities, durability, and any special features that make them stand out. It's a lot like buying a car, except these vehicles have an important job to do!

Step 4: Use and Maintenance

Once a power sweeper is sold, it begins its working life cleaning streets, parking lots, and other public spaces. These sweepers help remove debris like leaves, trash, and even small rocks that can make roads unsafe. To keep them running smoothly, regular maintenance is crucial. This means checking the engine, replacing worn-out brushes, and ensuring the suction systems are functioning properly. Without regular care, the sweeper might not work as well or could break down, just like any other vehicle.

Step 5: Repair and Upgrading

Even with the best care, parts of the sweeper will eventually need repair. Experts fix broken parts and sometimes upgrade the sweeper with newer, better components. Upgrading can include adding more powerful engines, advanced technology for better navigation, or more efficient sweeper brushes. These updates can extend the life of the machine and improve its performance.

Step 6: Disposal

All things must eventually come to an end, and power sweepers are no exception. When a sweeper is too old or too damaged to repair, it is time for disposal. However, disposal doesn't mean it's just thrown away. Often, parts of the machine can be recycled. Steel and aluminum are melted down and used to make new products. Recycling helps reduce waste and is good for the environment.

And there you have it — the lifecycle of power sweeping equipment from design to disposal. These hardworking machines have a critical role in keeping our streets clean and our communities beautiful. Next time you see one sweeping by, you'll know the fascinating journey it took to get there!